Fast Fashion

Fast Fashion is an upcoming, popular business model that relies on mass production, design, and marketing. The manufacturing scales focuses on replicating trendy styles with low-quality materials to produce inexpensive clothing for the general public at a fast pace. These cheaply-made, trendy items resulted in a large-scale movement that revolutionized the fashion industry.[2] This movement originated in the 1960s to promote paper and resulted in a push towards using cheap materials and disposable clothing. In the present day, fast fashion is known for efficient supply chains, responsive design methods, inexpensive labor, sweatshops, and bulk low-labor manufacturing industries located in various regions throughout Asia.[3] Fast fashion brands such as Uniqlo, H&M, and Zara built these business models, based on inexpensive clothing from efficient production lines, to create seasonal/trendy designs that are continuously marketed toward fashion-conscious consumers.[4]

Contents

Origins

The earliest version of fast fashion dates back to the 1960s with the paper clothing trend, where one viral marketing campaign instigated the movement through paper napkins. In an attempt to promote a new Dura-Weve material in 1966, Scott Paper Company created two styles of shift dresses. In eight months, 500,000 units were sold; by the end of 1966, national sales of paper clothes had topped $3.5 million. These paper clothes were designed to be easily disposable and reflected fashion as an artistic statement.[5] In 1968 paper clothing went out of style due to a shift in design trends and a cultural focus on the environment.[6] This trend prompted fast fashion businesses during the late 20th century to manufacture cloth cheaper and more efficiently, utilizing new materials like polyester and nylon.

Current Business Practices

Some of the current popular fast fashion brands include Zara, Shein, Uniqlo, H&M, ASOS, and Topshop. These businesses rely heavily on cheap labor and inexpensive global trade to quickly develop, construct, and distribute clothing.

In 2004, the Multifiber Arrangement (MFA), which previously imposed quotas and restricted clothing exports from developing countries to developed countries, was phased out. This further impacted fast fashion because without these quotas, importing clothing is now based on labor costs, local input materials, tariffs, and a firm's ability to produce trending clothing.[8] Due to the recent focus on labor costs, businesses lowered prices.

Zara's Business Practices

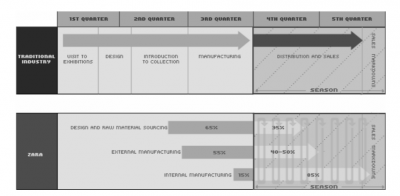

Fast fashion brands typically develop their seasonal clothing prior to the start of the season. It can be noted that Zara develops clothing up to nine months in advance.[9] Zara relies on sales data, store managers, industry publications, the internet, and trend spotters to get information on current trends. During the season, Zara can create clothing in four to five weeks and modify it in two weeks. The traditional industry model could take up to six months to complete the same process. At Zara, creative teams thus focus on "products for the current season by creating constant variation, expanding on successful product items and continuing in-season development, and on the following season and year by selecting the fabrics and product mix that would be the basis for an initial collection."[9] Due to the short design cycle, fast fashion companies like Zara can continually manufacture merchandise during the fashion season instead of just relying on execution before the season starts.

Technology in Fast Fashion Practices

Data Collection

Nowadays, fashion brands, including fast fashion and high-brand names, use modern technology to better understand their market and customers. Through online data collection, some companies can use Artificial Intelligence (AI) to reshape the company's approach to product design and development, which allows them to predict what customers will want to look for and buy next.[10] Big data analysis has already begun to take on a significant role in forecasting customer behavior and buying patterns. The brands with the resources and funds to obtain these analytics utilize this competitive advantage over other smaller businesses. Fast fashion brands can revamp their marketing tactics to find and create the best, most profitable products to bring to their consumers using big data analytics. Currently, to be successful within the fashion industry, brands need to predict fashion and industry trends to stay in touch with the ever-changing consumer preferences.[11] Big data analytics can provide companies with many valuable services, mainly through analyzing trends, identifying target markets, and improving cross-selling. Helping companies understand market trends by using data-driven sentiment analysis solutions on social media and other platforms ultimately aids them in creating and marketing their products correctly to keep up with the times.

Implementation of AI

AI is becoming the fore-front force in fast fashion practices. From design, manufacturing, logistic supply chain, and marketing, AI in the fashion industry is starting to transform how companies operate and maximize their profits. AI and machine learning (ML) based technologies provide automated solutions to provide the most efficient, cost-saving methods in the age of digitalization.

Designing Clothes

AI can act as a clothing designer because it can reduce forecasting errors by detecting new, in-demand trends. Since fashion trends can vary rapidly, AI designers need to keep up with the latest styles by analyzing designs through images to copy those popular styles.[13] Moreover, because the product life cycle is short and there can be up to 10,000 unique items (measured in stock-keeping units) to model, it is hard to forecast future trends using traditional means in a short amount of time. AI benefited forecasting despite these conditions and often includes multiple models working in conjunction.[14]

AI can also directly design clothing items. For example, Pinar Yanardag and Emily Salvador utilized AI to create a little black dress. They trained a GAN (Generative Adversarial Network), which generated designs for humans to then pick features from the designs to incorporate into the final design. The final design was then handmade.[15] In addition, certain jewelry creation uses a similar process.[12]

Manufacturing

AI also plays a role in manufacturing and supply chains. AI can perform labor-intensive tasks such as sewing and sorting with a faster speed and accuracy, therefore reducing the extra cost of employees. Fast fashion companies can also mass-produce their clothing because AI-enabled machines and robots can perfectly stitch the fabrics while detecting any material faults. In inventory and supply chain management, AI speeds up the product's routes by cutting the logistic supplies and shipping costs. Using these AI benefits, companies can offer faster delivery options and find alternate routes for vehicles if derailed by unforeseen circumstances.[16] Manufacturing marketplaces can also utilize AI to assess whether or not designs are feasible and can provide estimates on cost and production time, which potentially eliminates long periods of communication with suppliers. This is a crucial role for mass production because the more products they create and send out ultimately leads to more profit for the business. Oftentimes, vendors tend to be less responsive to small-quantity orders unless they are specifically set up for that scale because of the shift towards mass production and AI methods.[10]

Virtual Fitting Rooms

AI also provides virtual fitting rooms in which customers can virtually try on items. To achieve this, consumers provide their personal data such as the consumer's height, weight, and fit preferences, and this information is used in conjunction with AI and 3D cameras. These algorithms combine customer information with existing databases of various items, styles, and sizes to recommend the best products from brand partners to consumers. This allows for personalized recommendations and easier access to products with contactless methods.[17]

Ethical Implications

Amidst the rise of fast fashion, there are drawbacks concerning the ethical implications surrounding this movement. The high street fashion market relies on high product variety, low predictability, relatively low margins, and high levels of impulse purchasing.[18] One key component of the supply chain management aspect of fast fashion involves vertical disintegration and outsourcing products to independent subcontractors that generally are located within lower labor cost countries.[19] The goal of these companies is to continue to drive down prices. Previously, Hong Kong, South Korea, and Taiwan were popular locations for low-cost manufacturing labor, but currently, the more common locations include Bangladesh, Myanmar, and Cambodia.[19]

Ethical transgressions within supply chains pose a challenge to fast fashion in regards to child labor and worker exploitation. There are clear concerns as it is difficult to execute strategies that are competitive enough to keep up with the fashion industry alongside being socially responsible. Many of these nations where production occurs have poor working conditions, weak regulatory compliance, and corruption in the production contexts.[19] For example, in the U.S. about 90% of clothing is made from cotton or polyester, which are both associated with significant health implications from the manufacturing and production processes.[20] Within many of these factories there can be respiratory hazards from poor ventilation and musculoskeletal hazards from repetitive motion tasks, some of which lead to health debilitating and life-threatening health implications.[20]

One example of poor working conditions can be noted that occurred in Pakistan when there was a massive fire at Ali Enterprise textile factory in September 2012.[21] There were about 650 people working inside the factory, where 258 of the workers were killed. KiK (a German clothing retail company) was the factory’s main customer, and they ended up agreeing to pay $5.15 million to the affected families and survivors.[22] In addition, the fire spread so quickly because of safety standards that were violated, such as locked and blocked emergency exits.[21] This incident exemplifies what can be extremely poor and unsafe working conditions within factories that help fast fashion produce products as quickly and cheaply as possible. It can be seen as immoral for these workers to be working in such harsh conditions.

References

- ↑ https://www.pinterest.com/pin/317926054947599044/

- ↑ Linden, A. (2016). An Analysis of the Fast Fashion Industry. Retrieved 10 March 2021, from https://digitalcommons.bard.edu/cgi/viewcontent.cgi?article=1033&context=senproj_f2016

- ↑ Joy, A. (2012). Fast Fashion, Sustainability, and the Ethical Appeal of Luxury Brands. Retrieved 12 March 2021, from https://www3.nd.edu/~jsherry/pdf/2012/FastFashionSustainability.pdf

- ↑ Gustashaw, M. (20 March 2017). Uniqlo Is Going to Start Producing Clothing at Zara Speeds. Retrieved 12 March 2021, from https://www.gq.com/story/uniqlo-fast-fashion-speed-zara-competition

- ↑ Buck, S. (27 November 2017). This paper clothing trend of the 1960s was the early version of fast fashion. Retrieved 11 March 2021, from https://timeline.com/paper-fashion-1960s-43dd00590bce

- ↑ Cunningham, Patricia A., and Susan Voso Lab. Dress and Popular Culture. Bowling Green State University Popular Press, 1991.

- ↑ Stanton, A. (2019). What is Fast Fashion Anyway? Retrieved 12 March 2021, from https://www.thegoodtrade.com/features/what-is-fast-fashion

- ↑ Alam, M. S., et al. “The Apparel Industry in the Post‐Multifiber Arrangement Environment: A Review.” Wiley Online Library, John Wiley & Sons, Ltd, 10 Oct. 2018, onlinelibrary.wiley.com/doi/abs/10.1111/rode.12556.

- ↑ 9.0 9.1 9.2 Pankaj Ghemawat and Jose Luis Nueno Iniesta. ZARA: Fast Fashion. Boston: Harvard Business Publishing, 2003.

- ↑ 10.0 10.1 10.2 CB Insights. (13 October 2020). The Future Of Fashion: From Design To Merchandising, How Tech Is Reshaping The Industry. Retrieved 12 March 2021, from https://www.cbinsights.com/research/fashion-tech-future-trends/#:~:text=And%20today%2C%20fashion%20technology%20is,up%20every%20aspect%20of%20fashion

- ↑ Business Wire. (12 June 2020). How Big Data Analytics Is Changing the Face of Fashion Retail. Retrieved 12 March 2021, from https://www.businesswire.com/news/home/20200612005108/en/How-Big-Data-Analytics-Is-Changing-the-Face-of-Fashion-Retail-Quantzig%E2%80%99s-Experts-Share-Valuable-Insights-in-Their-Recent-Article#:~:text=In%20the%20fashion%20industry%2C%20data,customer%20behavior%20and%20buying%20patterns.&text=Big%20data%20analytics%20is%20helping,to%20bring%20to%20the%20market

- ↑ 12.0 12.1 Yanardag, Pinar, and Erin Genia. How to Generate (Almost) Anything, 2019, howtogeneratealmostanything.com/jewelry/2019/01/30/episode11.html.

- ↑ Bisen, V. (18 January 2020). How AI is Changing Fashion: Impact on the Industry with Use Cases. Retrieved 12 March 2021, from https://medium.com/vsinghbisen/how-ai-is-changing-fashion-impact-on-the-industry-with-use-cases-76f20fc5d93f

- ↑ Choi, Tsan-Ming, et al. “Fast Fashion Sales Forecasting with Limited Data and Time.” Decision Support Systems, vol. 59, 2014, pp. 84–92., doi:10.1016/j.dss.2013.10.008.

- ↑ Yanardag, Pinar, and Emily Salvador. The Little Black Dress, https://lbd-ai.com/.

- ↑ Schmelzer, R. (16 July 2019). The Fashion Industry is Getting More Intelligent with AI. Retrieved 12 March 2021, from https://www.forbes.com/sites/cognitiveworld/2019/07/16/the-fashion-industry-is-getting-more-intelligent-with-ai/?sh=15d0d973c74d

- ↑ Shemar, K. (August 2020). Fashion & AI: the privacy of virtual fitting rooms. Retrieved 12 March 2021, from https://www.gerrishlegal.com/legal-blog/2020/9/8/fashion-amp-ai-the-privacy-of-virtual-fitting-rooms

- ↑ Turker, D and Altuntas, C (2014) Sustainable supply chain management in the fast fashion industry: An analysis of corporate reports, European Management Journal, 32, pp 837-849

- ↑ 19.0 19.1 19.2 Perry, Patsy & Wood, Steve. (2019). Exploring the International Fashion Supply Chain and Corporate Social Responsibility: Cost, Responsiveness and Ethical Implications. https://eu-st01.ext.exlibrisgroup.com/44SUR_INST/storage/alma/7F/D5/06/81/9C/F2/42/58/15/68/9D/81/CD/08/FC/3A/__homes.surrey.ac.uk_home_.System_Desktop_Exploring%20the%20International%20Fashion%20Supply%20Chain%20and%20CSR_Perry_Wood%20chapter%202019.pdf?Expires=1616182605&Signature=Sm3e5NhwTFD1me9ZvZeorNfPQVaPdqU-0xirjkafR00SlQAnuYi3MB3iKGOvnCbAVfGLWDOQbNU1b8wkRuEdtW0Ns49w6CNoBoPa3Y-EahxRA8ZkXNocI1UsOH0kcmFW4NfRac8dGq9D73PBnO9LD9EiWuG7dAxttziT3C570RnJW4FURVMqDm7W-cJf~QqTkL3p4ztxh~utrlTNB9uaglCmCLvIQmrf81~oOn1MEkyUh4X4fOxrPbRFYlfFhKfSGPzEzKCWqZ52kdiDKhxLsZOXSQ2C1omeBqNeAaKATclliDaPYaHeyR3SRcN1HrmFh~yZzxVpJ4j9oFsb3J5l5Q__&Key-Pair-Id=APKAJ72OZCZ36VGVASIA

- ↑ 20.0 20.1 Bick, R., Halsey, E. & Ekenga, C.C. The global environmental injustice of fast fashion. Environ Health 17, 92 (2018). https://doi.org/10.1186/s12940-018-0433-7

- ↑ 21.0 21.1 Saif-ul-Islam M, Shaik MA, Shahid MU, Karim R, Ishtiaq M (2019) The Impact of Worst Fire Prevention Plan and Disaster Management at High Density Urban-Area: A Case Study of Ali Enterprises. Glob Environ Health Saf. 2019, Vol 3:2.https://www.researchgate.net/profile/Mohsin-Shaikh-3/publication/332110927_The_Impact_of_Worst_Fire_Prevention_Plan_and_Disaster_Management_at_High_Density_Urban-Area_A_Case_Study_of_Ali_Enterprises/links/5ca1b434a6fdccd46047f75b/The-Impact-of-Worst-Fire-Prevention-Plan-and-Disaster-Management-at-High-Density-Urban-Area-A-Case-Study-of-Ali-Enterprises.pdf

- ↑ Shams, Shamil (September 2, 2017). German retailer KiK compensates Pakistan's 'industrial 9/11' families. https://www.dw.com/en/german-retailer-kik-compensates-pakistans-industrial-9-11-families/a-37470138