Difference between revisions of "3D printing"

| Line 6: | Line 6: | ||

In the 1980s, 3D printing was more commonly referred to as rapid prototyping (RP) technologies.<ref>https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/ </ref> In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute filed for the first patent application for RP technology after inventing two AM construction methods of a 3D plastic model. <ref>Hideo Kodama, "A Scheme for Three-Dimensional Display by Automatic Fabrication of Three-Dimensional Model," IEICE TRANSACTIONS on Electronics (Japanese Edition), vol.J64-C, No.4, pp.237–241, April 1981</ref> | In the 1980s, 3D printing was more commonly referred to as rapid prototyping (RP) technologies.<ref>https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/ </ref> In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute filed for the first patent application for RP technology after inventing two AM construction methods of a 3D plastic model. <ref>Hideo Kodama, "A Scheme for Three-Dimensional Display by Automatic Fabrication of Three-Dimensional Model," IEICE TRANSACTIONS on Electronics (Japanese Edition), vol.J64-C, No.4, pp.237–241, April 1981</ref> | ||

| − | In 1986, Charles "Chuck" Hull issued a patent for stereolithography apparatus (SLA). This would later be known as one of the earlier 3D printers. Stereolithography works by exposing a vat of liquid photopolymer, an acrylic-based material, with a UV laser beam. The UV laser beam traces the first layer of an object onto the surface of the liquid, and as that portion is exposed to the UV beam, it hardens into plastic. This process is continued on for many more layers, until the whole object is printed out. <ref> http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx</ref> As this process had already been founded by Dr. Kodama, Hull's significant role in stereolithography was the design of the [[Wikipedia:STL (file format)|STereoLithography (STL) file format]]that most 3D printing softwares can interpret to begin producing material. | + | In 1986, Charles "Chuck" Hull issued a patent for stereolithography apparatus (SLA). This would later be known as one of the earlier 3D printers. Stereolithography works by exposing a vat of liquid photopolymer, an acrylic-based material, with a UV laser beam. The UV laser beam traces the first layer of an object onto the surface of the liquid, and as that portion is exposed to the UV beam, it hardens into plastic. This process is continued on for many more layers, until the whole object is printed out. <ref> http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx</ref> As this process had already been founded by Dr. Kodama, Hull's significant role in stereolithography was the design of the [[Wikipedia:STL (file format)|STereoLithography (STL) file format]] that most 3D printing softwares can interpret to begin producing material. |

AM processes also include [[Wikipedia:Selective laser sintering|Selective laser sintering (SLS)]] during which lasers meld layers of | AM processes also include [[Wikipedia:Selective laser sintering|Selective laser sintering (SLS)]] during which lasers meld layers of | ||

| − | powdered material together to produce a solid object, as well as multi-jet modelling (MJM), which also builds up an object by | + | powdered material together to produce a solid object, as well as multi-jet modelling (MJM), which also builds up an object by using an inkjet print head to spray a binder solution that will glue together layers of powder.<ref>http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx</ref> |

| + | |||

| + | ==Usage== | ||

| + | In 2005, the [[Wikipedia:RepRap Project|RepRap Project]] was founded in England, and marked the advent of an open-source community working to make 3D printing technologies available for everyone; and so, all designs were released under the GNU General Public License, a free software license. <ref> http://reprap.org/wiki/RepRapGPLLicence</ref> Following the RepRap project came the BfB RapMan 3D printer, the first 3D printer intended for commercial use. <ref> https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/</ref> Shortly after, [[Wikipedia:MakerBot|MakerBot]] was founded in 2009. MakerBot sold do-it-yourself styled kits, putting onto the market the possibility for consumers of all types to access and learn this technology to produce their own products and designs. <ref>http://faculty.poly.edu/~brao/3dppicmet.pdf</ref> | ||

| + | |||

| + | 3D printing can be used to create almost any kind of static product model and prototype - from jewelry to tools to a full-sized house.<ref>http://www.bbc.com/news/technology-27221199</ref> The automotive industry as well as aviation sector can use 3D printing to make prototypes of vehicle parts. Architects can use 3D printing to create models of their projects. The medical field can utilize 3D printing to produce prosthetics and artificial teeth for their patients, or even replicas of organs to help prepare for surgery. <ref>http://www.pcmag.com/article2/0,2817,2394720,00.asp</ref> In Sudan, Not Impossible labs created Project Daniel, which worked to print prosthetic arms for Daniel, a teen who had lost his arms as a result of violence. <ref> http://www.notimpossiblenow.com/labs/project-daniel </ref> 3D printing can also be used in the engineering field to produce printed electronics, allowing layered circuitry and devices to be printed on flexible material, or in the culinary field to help with food preparation.<ref>http://www.pcmag.com/article2/0,2817,2394720,00.asp</ref> | ||

| + | |||

| + | ==Benefits== | ||

==Concerns== | ==Concerns== | ||

Revision as of 04:08, 21 February 2017

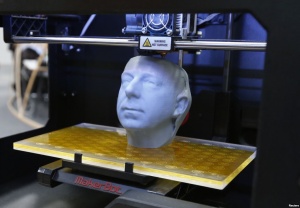

3D printing is the popular term that refers to additive manufacturing (AM) technologies [1]. It is "additive" because it creates a three-dimensional (3D) object by layering materials upon one another, building up the object from scratch rather than removing material.[2] 3D printers possess the ability to take digital model data, created on either a computer-aided design (CAD), computer-aided manufacturing (CAM) program, or from an Additive Manufacturing File (AMF) file, and transform it into physical objects.[3]

Contents

History

In the 1980s, 3D printing was more commonly referred to as rapid prototyping (RP) technologies.[4] In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute filed for the first patent application for RP technology after inventing two AM construction methods of a 3D plastic model. [5]

In 1986, Charles "Chuck" Hull issued a patent for stereolithography apparatus (SLA). This would later be known as one of the earlier 3D printers. Stereolithography works by exposing a vat of liquid photopolymer, an acrylic-based material, with a UV laser beam. The UV laser beam traces the first layer of an object onto the surface of the liquid, and as that portion is exposed to the UV beam, it hardens into plastic. This process is continued on for many more layers, until the whole object is printed out. [6] As this process had already been founded by Dr. Kodama, Hull's significant role in stereolithography was the design of the STereoLithography (STL) file format that most 3D printing softwares can interpret to begin producing material.

AM processes also include Selective laser sintering (SLS) during which lasers meld layers of powdered material together to produce a solid object, as well as multi-jet modelling (MJM), which also builds up an object by using an inkjet print head to spray a binder solution that will glue together layers of powder.[7]

Usage

In 2005, the RepRap Project was founded in England, and marked the advent of an open-source community working to make 3D printing technologies available for everyone; and so, all designs were released under the GNU General Public License, a free software license. [8] Following the RepRap project came the BfB RapMan 3D printer, the first 3D printer intended for commercial use. [9] Shortly after, MakerBot was founded in 2009. MakerBot sold do-it-yourself styled kits, putting onto the market the possibility for consumers of all types to access and learn this technology to produce their own products and designs. [10]

3D printing can be used to create almost any kind of static product model and prototype - from jewelry to tools to a full-sized house.[11] The automotive industry as well as aviation sector can use 3D printing to make prototypes of vehicle parts. Architects can use 3D printing to create models of their projects. The medical field can utilize 3D printing to produce prosthetics and artificial teeth for their patients, or even replicas of organs to help prepare for surgery. [12] In Sudan, Not Impossible labs created Project Daniel, which worked to print prosthetic arms for Daniel, a teen who had lost his arms as a result of violence. [13] 3D printing can also be used in the engineering field to produce printed electronics, allowing layered circuitry and devices to be printed on flexible material, or in the culinary field to help with food preparation.[14]

Benefits

Concerns

Intellectual Property Rights

Finally, given the ease with which certain objects can now be replicated, it remains to be seen whether changes will be made to current copyright legislation so as to protect intellectual property rights with the new technology widely available.

Misuse

Labor Substitution

Continuing Advancements

4D Printing

4D printing incorporates one more dimension: the function of time. The team dubbed "Self-Assembly Lab"[15] at Massachusetts Institute of Technology collaborated with Stratasys, a major 3D printing manufacturer, and the software corporation Autodesk Inc to develop a custom-built and adaptable technology[16].

As an extension of 3D printing, 4D printing aims to skip the step of assembling the printed material ourselves to having them self-assemble as well as autonomously reshape over time. These programmable materials are created with multi-material 3D printing and their responses to changes in environment (mimicked with simple energy inputs of water, heat, and light), as well as geometric code [17].

Skylar Tibbits, a co-director and founder of Self-Assembly Labs, gave a demonstration of 4D printing at a TED Talk in 2013 [18], showing how a single 1D strand dipped in water could proceed to self-fold into the letters 'M I T'.

Concerns

This complex technology introduces many possibilities in engineering. It has already appeared in several businesses, such as sportswear, but soon, the focus may shift from the inorganic world to organic life. Following the same concerns that arise from 3D printing, there is also opportunity for misuse of the programmable matter, and issues in regulation concerning intellectual property law and patenting[19].

References

- ↑ http://faculty.poly.edu/~brao/3dppicmet.pdf

- ↑ Kumar, Upender, Manoj Pandey, and Tejender Singh Rawat. "Review on 3D Printing Technology and Possible Technological Improvements" <http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx

- ↑ http://www.pcmag.com/article2/0,2817,2394720,00.asp

- ↑ https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/

- ↑ Hideo Kodama, "A Scheme for Three-Dimensional Display by Automatic Fabrication of Three-Dimensional Model," IEICE TRANSACTIONS on Electronics (Japanese Edition), vol.J64-C, No.4, pp.237–241, April 1981

- ↑ http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx

- ↑ http://www.academicscience.co.in/admin/resources/project/paper/f201505111431317592.docx

- ↑ http://reprap.org/wiki/RepRapGPLLicence

- ↑ https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/

- ↑ http://faculty.poly.edu/~brao/3dppicmet.pdf

- ↑ http://www.bbc.com/news/technology-27221199

- ↑ http://www.pcmag.com/article2/0,2817,2394720,00.asp

- ↑ http://www.notimpossiblenow.com/labs/project-daniel

- ↑ http://www.pcmag.com/article2/0,2817,2394720,00.asp

- ↑ http://www.selfassemblylab.net/

- ↑ http://www.selfassemblylab.net/4DPrinting.php

- ↑ http://www.smithsonianmag.com/innovation/Objects-That-Change-Shape-On-Their-Own-180951449/

- ↑ https://www.ted.com/talks/skylar_tibbits_the_emergence_of_4d_printing

- ↑ http://www.atlanticcouncil.org/images/publications/The_Next_Wave_4D_Printing_Programming_the_Material_World.pdf